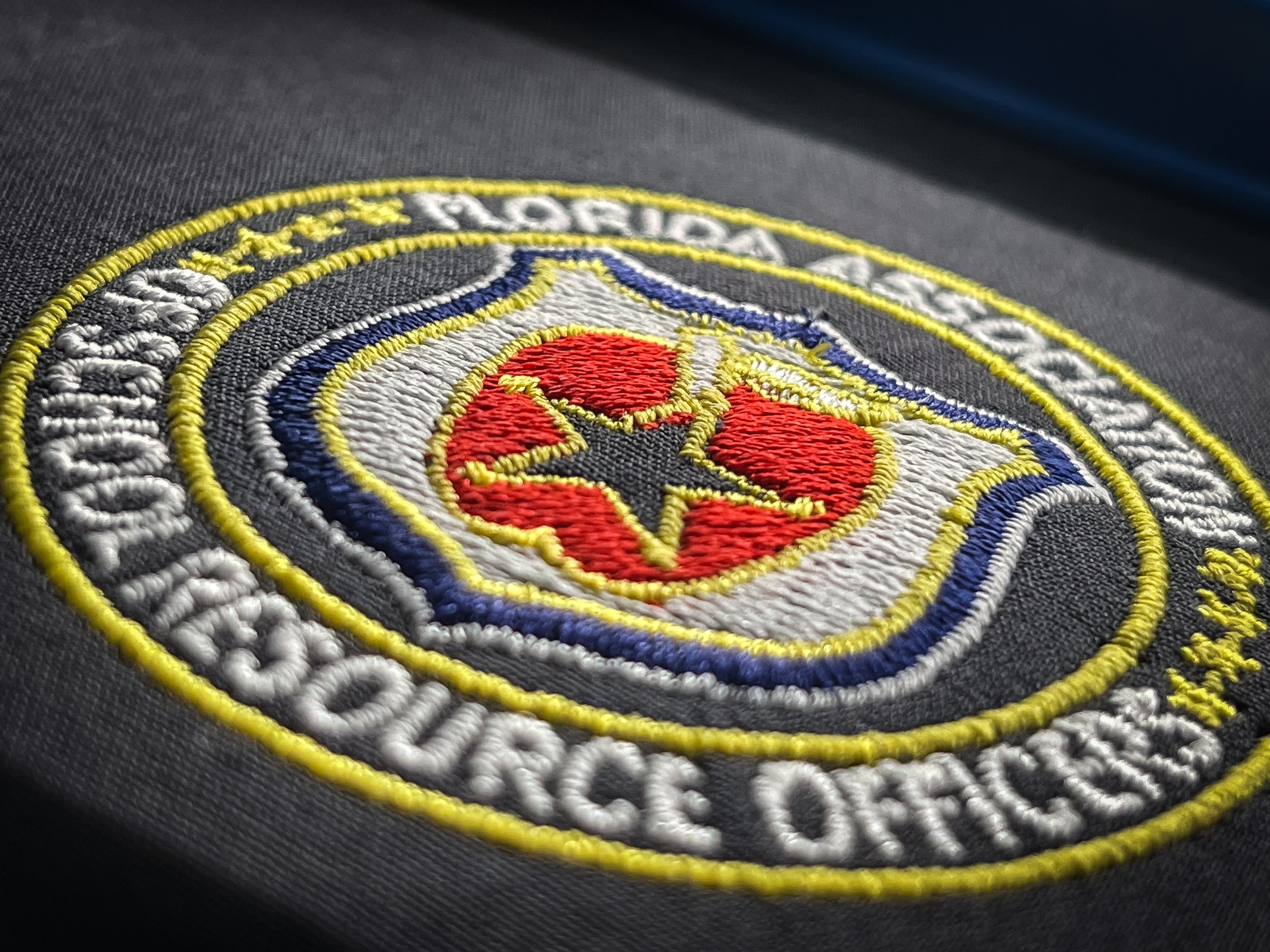

Custom Embroidery

Looking to add a personal touch to your clothing, hats or accessories?

At Signco Designs, we offer high-quality embroidery services for all your needs.

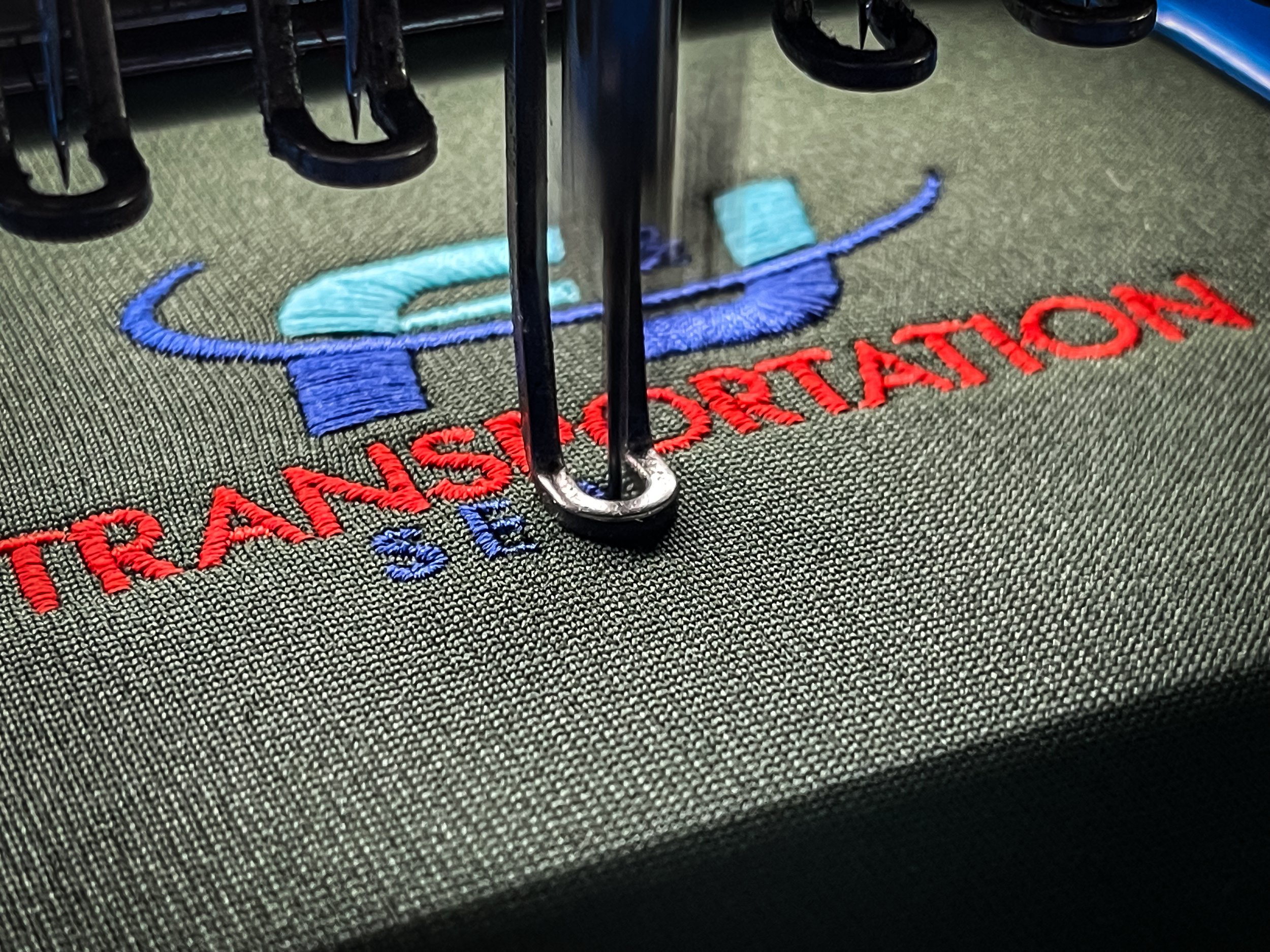

We can turn your ideas into beautiful designs that will make your items stand out. Whether you need custom embroidery for your business, sports team, or personal use, we can handle it all. We use top-of-the-line embroidery machines and high-quality materials to ensure that your designs are vibrant and long-lasting.

Our embroidery services cover a wide range of items, including shirts, hats, bags, towels, and more. You can choose from a variety of thread colors and styles to make your design truly personalized. We will work with you to ensure that the design fits your vision and that you are satisfied with the final product.

In addition to custom embroidery, we also offer digitization services to turn your existing designs into embroidery files. This means that you can easily add your logo or design to any item in the future.

At Signco Designs, we pride ourselves on our exceptional customer service and quick turnaround times. We understand the importance of getting your items back to you in a timely manner, and we work hard to ensure that all orders are completed as efficiently as possible.

Ready to add a unique touch to your items with custom embroidery? Contact us today to learn more about our services and get a quote.

We specialize in specialty embroidery!

From 3D embroidery, specialty threads and every technique in between we can create unique one-of-a-kind items for you!

3D Embroidery

Specialized foam is stitched underneath to create a 3D effect which adds dimension to your design!

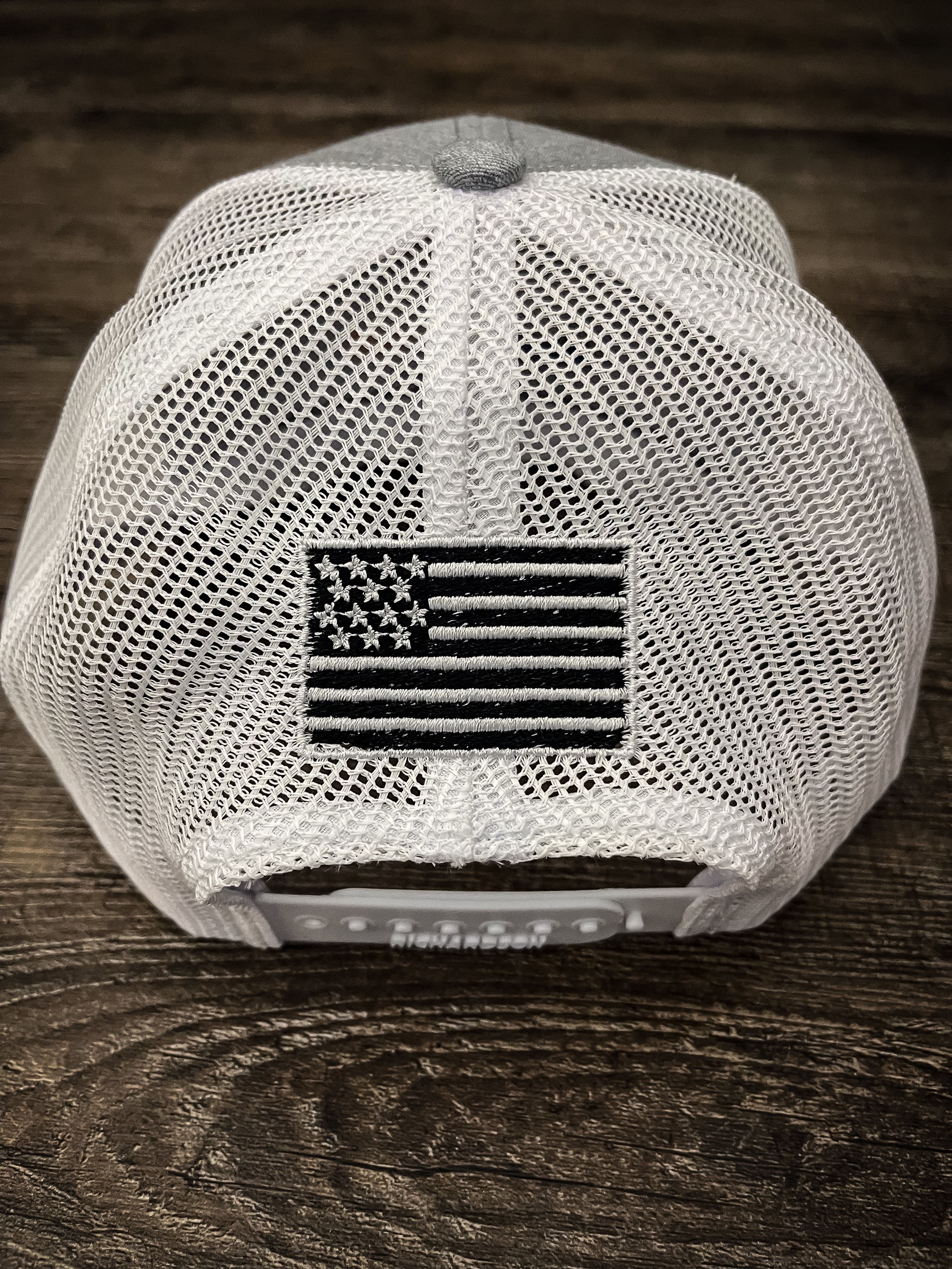

Side/Back Branding

We can embroider on unique locations to give you more options when customzing your final product.

Specialty Threads

We offer a wide-range of speciality threads from variegreted, frosted matte, glow-in-the-dark and more.

Shoe/Clamp Embroidery

With our unique embroidery accessories and speciality clamps we can embroider on pretty much everything!